Manufacturing industries are always searching for faster, cleaner, and more accurate production methods. One technology that has become very popular in recent years is laser engraving. This modern method is used in many industries for marking, designing, and customizing products. It offers high precision, speed, and long-lasting results.

Laser engraving is widely used in product manufacturing, branding, and industrial marking. It helps businesses create detailed designs and clear markings on different materials. This article explains what laser engraving is and why it has become so important in modern manufacturing.

Understanding Laser Engraving

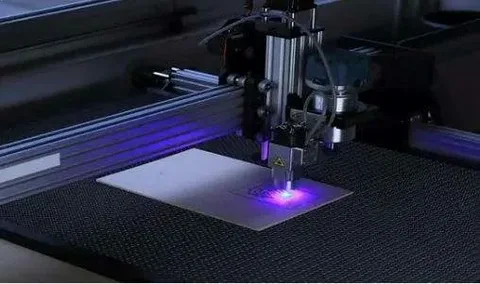

Laser engraving is a process that uses a laser beam to create designs, text, or markings on surfaces. The laser removes a small amount of material from the surface to create permanent markings. This process is controlled by computer software, which ensures accurate and consistent results.

What Is Laser Technology?

Laser stands for Light Amplification by Stimulated Emission of Radiation. A laser machine produces a strong and focused beam of light. This beam is directed onto the surface of a material to create markings or designs.

The laser beam works by heating or removing a small part of the surface. This creates clear and detailed engravings without damaging the surrounding material.

How Laser Engraving Works

Laser engraving machines use computer programs to control the engraving process. The operator selects or designs the pattern using software. The machine then follows the design and engraves it onto the material.

The process is fast and highly accurate. It can create simple text or complex patterns with perfect detail.

Materials Used in Laser Engraving

One of the main reasons for the popularity of laser engraving is its ability to work on many materials.

Metal Engraving

Laser engraving is commonly used on metals such as stainless steel, aluminum, and brass. It is widely used for industrial marking, product labeling, and decorative designs.

Plastic and Acrylic Engraving

Plastic and acrylic materials are easy to engrave using laser technology. These materials are often used in signage, branding, and display products.

Wood and Leather Engraving

Laser engraving is also popular in wood and leather industries. It is used for furniture decoration, gift items, and artistic designs.

Glass Engraving

Laser engraving creates attractive designs on glass products. It is often used in awards, trophies, and decorative items.

High Precision and Accuracy

Laser engraving is known for its high level of precision. Modern manufacturing requires detailed and accurate markings, and laser technology provides this advantage.

Creating Detailed Designs

Laser engraving machines can create very small and detailed designs. They can engrave text, logos, and patterns with perfect clarity. This level of detail is difficult to achieve with traditional engraving methods.

Consistent Quality

Laser engraving provides the same quality for every product. Computer-controlled machines ensure that each engraving is identical. This is very important for industries that produce large quantities of products.

Faster Production Process

Speed is another major reason why laser engraving is popular in manufacturing.

Quick Engraving Time

Laser engraving machines work quickly compared to manual engraving methods. Faster production helps businesses complete orders on time and increase productivity.

Suitable for Mass Production

Laser engraving machines can handle large production volumes. They can engrave multiple items without reducing quality. This makes them ideal for manufacturing industries.

Long-Lasting and Durable Markings

Laser engravings are permanent and resistant to damage. This makes them suitable for industrial and commercial use.

Resistance to Wear and Tear

Laser engravings do not fade or wear easily. They remain clear even after long-term use. This is important for product identification and branding.

Suitable for Harsh Environments

Products used in industries often face heat, chemicals, and moisture. Laser engravings remain visible even in tough conditions, making them reliable for industrial applications.

Supporting Product Customization

Modern customers prefer personalized products. Laser engraving allows manufacturers to create customized items easily.

Personalization of Products

Laser engraving is widely used for customizing gifts, promotional items, and corporate products. It allows businesses to add names, logos, and special designs.

Flexible Design Options

Laser engraving software allows manufacturers to create unlimited design options. Businesses can easily change designs based on customer needs.

Environmentally Friendly Process

Laser engraving is considered an eco-friendly manufacturing method.

Reduced Material Waste

Laser engraving removes only a small amount of material. This reduces waste and helps businesses use resources efficiently.

No Chemical Usage

Traditional engraving methods sometimes use chemicals. Laser engraving does not require harmful chemicals, making it safer for the environment and workers.

Low Maintenance and Cost Efficiency

Laser engraving machines are designed for long-term use with minimal maintenance.

Reduced Maintenance Requirements

Laser engraving machines have fewer moving parts compared to traditional machines. This reduces wear and tear and lowers maintenance costs.

Cost-Effective Production

Although the initial cost of laser machines may be high, they provide long-term savings. Faster production and low maintenance help businesses reduce overall expenses.

Wide Industrial Applications

Laser engraving is used in many industries because of its versatility and efficiency.

Manufacturing and Engineering

Manufacturers use laser engraving for product marking, serial numbers, and part identification. It helps maintain product tracking and quality control.

Advertising and Branding

Laser engraving is used to create promotional products, signage, and branding materials. It helps businesses create professional and attractive product designs.

Jewelry and Gift Industry

Laser engraving is widely used in jewelry making and gift customization. It allows businesses to create unique and personalized products.

Medical and Electronic Industries

Laser engraving is used to mark medical instruments and electronic components. Permanent markings help in identification and quality assurance.

Safety and Reliability

Modern laser engraving machines include safety features to protect workers and equipment.

Safe Operation

Laser machines are designed with protective systems that prevent accidental exposure to laser beams. This ensures safe working conditions.

Reliable Performance

Computer-controlled machines reduce human errors. This improves reliability and maintains high-quality engraving results.

Future of Laser Engraving in Manufacturing

Technology continues to improve laser engraving systems. Future developments will make engraving even faster and more accurate.

Integration with Automation

Laser engraving machines are being connected with automated production systems. This improves manufacturing speed and reduces manual work.

Advanced Software Technology

Future software systems will provide better design options and improved machine control. This will help manufacturers create more complex designs easily.

Increased Industrial Demand

As industries continue to focus on precision and customization, the demand for laser engraving is expected to grow.

Conclusion

Laser engraving has become an essential part of modern manufacturing. It offers high precision, speed, and long-lasting results. The ability to engrave different materials makes it suitable for many industries.

Laser engraving supports product customization, improves branding, and reduces production time. It is also environmentally friendly and cost-effective. These benefits make laser engraving a preferred choice for businesses around the world.

As technology continues to improve, laser engraving will become even more advanced. It will continue to support manufacturing industries by providing accurate, efficient, and high-quality engraving solutions.

For more insightful articles related to this topic, feel free to visit: baddiehub.pics