Plasma Arc Welding (PAW) has become a dependable choice for industries that need precise, repeatable, and high-quality welds. From aerospace components to medical devices and heavy-duty manufacturing, PAW offers a level of control that conventional processes often struggle to match. This article breaks down how Plasma Arc Welding works, the core parts involved, and what professionals should keep in mind when selecting or operating PAW equipment.

What Plasma Arc Welding Is

Plasma Arc Welding is an advanced arc welding process that uses a constricted arc to generate a focused, high-temperature plasma jet. This jet creates a stable and concentrated heat source capable of producing narrow, deep welds with minimal distortion.

Compared with TIG welding, PAW delivers higher energy density, better control over arc shape, and improved consistency in automated setups.

Why Industries Use Plasma Arc Welding

Businesses choose PAW for three main reasons:

Precision. The narrow plasma column allows for clean weld seams and tight control, even on thin materials.

Speed. The process supports faster travel speeds and deeper penetration, which translates into higher productivity.

Stability. Once set, the arc remains steady. This makes PAW suitable for robotic cells or long production runs where repeatability matters.

These advantages help manufacturers reduce rework, maintain high quality standards, and keep production lines moving.

Key Parts of a Plasma Arc Welding System

A Plasma Arc Welding setup has several core components. Each one affects arc stability, weld quality, and system reliability.

Plasma Torch

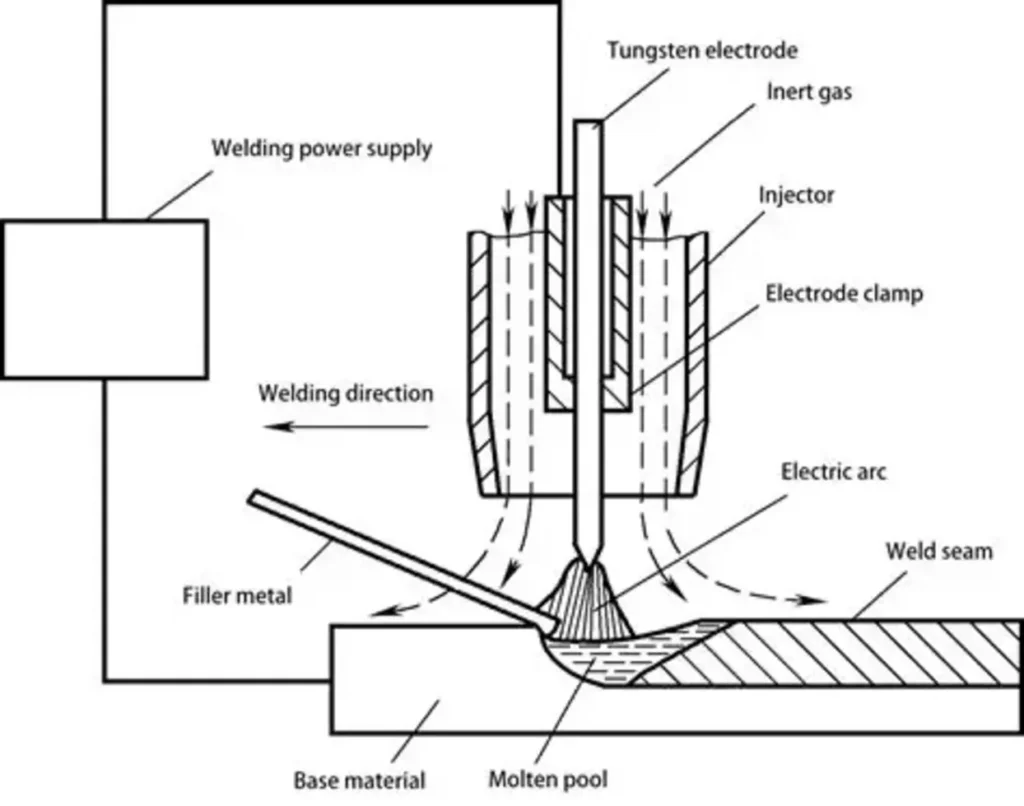

The plasma torch is the heart of the system. It’s designed to constrict the arc and direct the plasma jet onto the workpiece. A typical torch includes:

Electrode: Usually made from tungsten to withstand high temperatures.

Nozzle (orifice): Shapes and constricts the arc. Different orifice sizes are used depending on material type and thickness.

Gas passages: Deliver plasma and shielding gas around the arc.

A good torch maintains consistent gas flow and resists overheating, which is essential for accuracy.

Electrode Assembly

The electrode generates the arc when current passes through it. In PAW, the arc forms between the electrode and the inside of the torch nozzle (transferred or non-transferred mode). The electrode’s composition, shape, and condition directly affect arc stability and plasma jet intensity.

Plasma Gas and Shielding Gas

PAW typically uses two types of gases:

Plasma gas: Often argon or a mix of argon and hydrogen. It’s ionized to form the plasma jet.

Shielding gas: Protects the molten pool from oxidation. This may be argon, nitrogen, or a blend depending on material.

The correct gas combination helps produce clean welds and consistent penetration.

Power Supply

A stable, high-frequency power source is required to start and maintain the arc. Most PAW power supplies allow fine adjustments of amperage and pulse settings. This level of control is especially helpful in applications where weld geometry must remain uniform across long production cycles.

Cooling System

Because PAW generates intense heat, the torch and cable assemblies rely on water cooling. A reliable cooling unit prevents overheating, prolongs torch life, and reduces downtime.

Control Console

Operators use the control panel to set welding parameters such as current, gas flow, pilot arc settings, and torch travel speed. An intuitive interface makes it easier for technicians to achieve consistent results across shifts.

How Plasma Arc Welding Works

Although PAW is more sophisticated than standard TIG welding, the process follows a clear sequence.

Step 1: Creating the Pilot Arc

The system initiates a small pilot arc between the tungsten electrode and the torch nozzle. This arc ionizes the plasma gas and prepares the main welding arc.

Step 2: Forming the Plasma Jet

Once the pilot arc is stable, the power supply increases current, allowing the main arc to transfer from the electrode to the workpiece. The nozzle constricts the arc, which turns the ionized gas into a high-velocity plasma jet. This jet can reach temperatures above 25,000°C.

Step 3: Heating and Melting the Metal

The focused plasma jet melts the surface of the workpiece. Because the heat is so concentrated, the weld pool remains narrow and controlled. This is ideal for delicate or high-tolerance parts.

Step 4: Solidifying the Weld

As the torch moves, molten metal solidifies behind it. Shielding gas protects the weld from contaminants, ensuring a clean finish.

Practical Considerations for Professionals

When selecting or operating Plasma Arc Welding equipment, keep these points in mind:

Match the orifice size to your application. Smaller openings create tighter arcs for thin materials, while larger nozzles suit thicker sections.

Monitor electrode wear. A worn electrode can destabilize the plasma jet and reduce weld quality.

Use consistent gas flow rates. Variations in flow can change arc shape and cause uneven penetration.

Invest in robust cooling. Heat buildup is one of the most common causes of torch failure.

Choose systems with strong process controls. Digital power supplies and automated consoles help maintain repeatability in production environments.

Industries That Benefit Most

Plasma Arc Welding is well-suited for sectors where precision and reliability are non-negotiable:

- Aerospace component manufacturing

- Medical device production

- Automotive and electric-vehicle parts

- Tooling and mold repair

- Stainless steel and non-ferrous fabrication

Its ability to deliver clean, repeatable welds makes it a dependable choice where quality cannot be compromised.

Final Thoughts

Plasma Arc Welding offers a powerful combination of precision, speed, and stability. By understanding the key parts of the system and how the process works, welding professionals can make informed decisions when selecting equipment or optimizing production lines. For manufacturers that need high-quality welds with tight tolerances, PAW remains one of the most capable options available.

Post by toko baut mur – tokohasil