Offshore oil and gas operations are among the most demanding industrial environments in the world. Subsea pipelines must transport hydrocarbons across vast distances under high pressures and extreme temperatures while resisting corrosion, water ingress, and mechanical damage. In these challenging conditions, insulation systems are not merely protective layers—they are critical components that ensure flow assurance, structural stability, and long-term operational reliability.

Among the most advanced materials used in offshore insulation are engineered polyol systems, which form the backbone of high-performance polyurethane and polyisocyanurate foams. These systems are carefully formulated to meet the stringent performance requirements of offshore environments. By combining precise chemical engineering with application-specific design, engineered polyol systems provide long-term thermal efficiency, structural integrity, and environmental resistance for subsea pipeline insulation.

The Demanding Nature of Offshore Pipeline Environments

Offshore pipelines operate in environments characterized by high hydrostatic pressure, corrosive seawater, mechanical stress, and fluctuating temperatures. At deepwater depths, external pressures can reach thousands of psi, while internal pipeline temperatures may vary significantly depending on the transported fluid.

Without proper insulation, subsea pipelines face several operational risks. Heat loss can lead to the formation of hydrates and wax deposits, which obstruct flow and increase maintenance costs. Thermal contraction and expansion can induce stress in pipeline structures. Additionally, long-term exposure to moisture can compromise insulation performance if the material is not engineered for water resistance.

In such a setting, insulation systems must provide:

- Low thermal conductivity over extended service life

- High compressive strength under hydrostatic pressure

- Resistance to water absorption

- Dimensional stability across temperature cycles

- Compatibility with protective coatings and outer sheathing

Engineered polyol systems are specifically designed to meet these multi-dimensional requirements.

NOTE:- Polyol for Pip-in-Pipe Insulation was developed to support high-performance insulation systems in deepwater pipeline installations. It was recognized for minimizing heat loss and improving operational efficiency. Reliable performance under pressure and temperature variations was delivered. IP Harwal Polymer was chosen for quality assurance. Reach out to IP Harwal Polymer today.

Understanding Engineered Polyol Systems

Polyol systems are essential components in the production of polyurethane and polyisocyanurate foams. A polyol is a chemical compound containing multiple hydroxyl groups, which react with isocyanates to form polymer structures. However, in offshore insulation applications, standard polyol formulations are insufficient.

Engineered polyol systems are customized blends that include:

- Base polyols tailored for specific mechanical and thermal properties

- Catalysts to control reaction kinetics

- Surfactants to manage cell structure

- Blowing agents to create uniform foam density

- Flame retardants and stabilizers for enhanced safety and durability

The engineering process focuses on optimizing molecular structure, crosslink density, and foam morphology to achieve superior insulation performance under offshore conditions.

Thermal Performance and Flow Assurance

One of the primary functions of offshore pipeline insulation is maintaining the temperature of transported fluids. Hydrocarbon streams, particularly in deepwater production, are vulnerable to rapid cooling in cold seabed conditions. If temperatures drop below critical thresholds, hydrates and paraffin waxes can form, blocking pipelines and causing costly shutdowns.

Engineered polyol systems produce closed-cell polyurethane or polyisocyanurate foams with exceptionally low thermal conductivity. The closed-cell structure traps blowing agents within microscopic cells, minimizing heat transfer through conduction and convection.

More importantly, these systems are designed to maintain their thermal performance over decades. Properly engineered cell stability reduces gas diffusion and prevents significant increases in thermal conductivity over time. This ensures long-term reliability in maintaining flow assurance.

Mechanical Strength Under Hydrostatic Pressure

Deepwater pipelines are subjected to intense hydrostatic pressures that can compress insulation materials. If the insulation lacks sufficient compressive strength, it may deform, lose thickness, and compromise thermal performance.

Engineered polyol systems are formulated to produce high-density foams with optimized crosslink structures. This increases compressive strength and enhances resistance to creep under sustained pressure. The result is an insulation layer capable of maintaining dimensional integrity even at extreme depths.

By carefully controlling foam density and polymer architecture, manufacturers can tailor the mechanical performance of the insulation to specific water depths and operational conditions.

Water Resistance and Long-Term Durability

Water ingress is one of the greatest threats to insulation longevity. When insulation absorbs water, its thermal conductivity increases significantly, reducing efficiency and potentially accelerating pipeline corrosion.

Engineered polyol systems generate closed-cell foams with minimal water absorption. The uniform cell structure and hydrophobic polymer matrix act as barriers to moisture penetration. Additionally, stabilizers and additives are incorporated to enhance resistance to hydrolytic degradation.

Over time, this resistance to water absorption ensures that the insulation maintains consistent performance, even after prolonged exposure to seawater and high-pressure conditions.

Dimensional Stability Across Temperature Cycles

Offshore pipelines experience temperature fluctuations during startup, shutdown, and operational changes. These thermal cycles can induce expansion and contraction within insulation materials.

Engineered polyol systems are designed with a balance of flexibility and rigidity to accommodate such movement without cracking or delaminating. Controlled crosslink density provides structural stability while maintaining sufficient resilience to absorb thermal stress.

This dimensional stability reduces the risk of insulation failure, thereby maintaining the protective envelope around the pipeline and extending its service life.

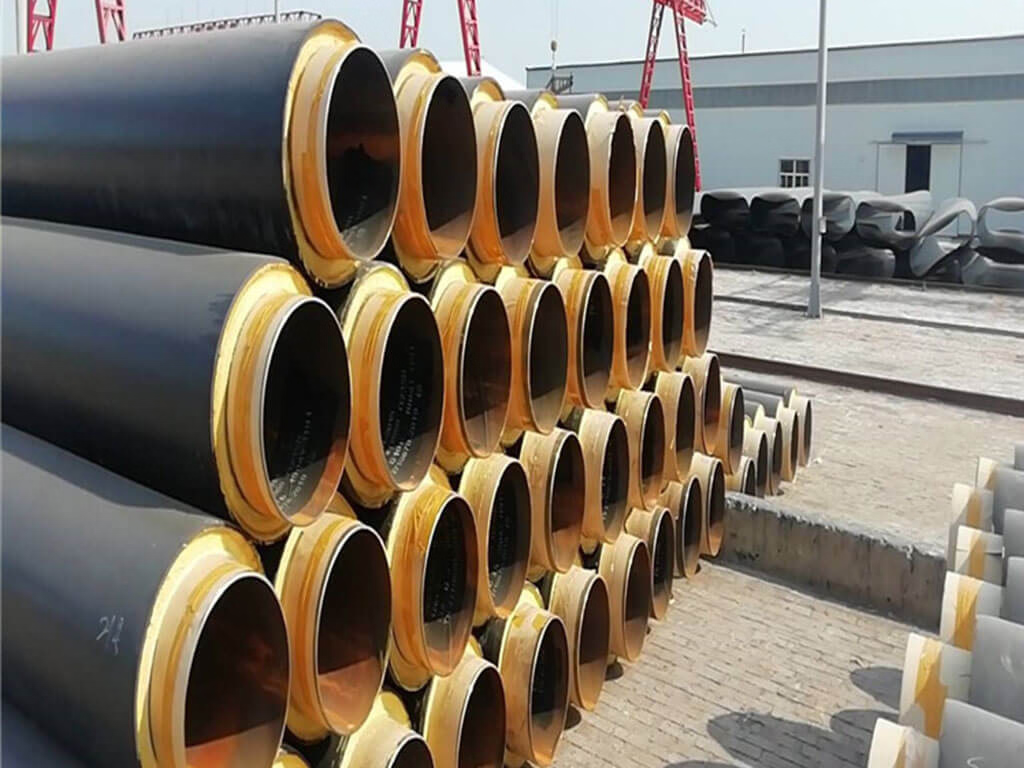

Compatibility With Coatings and Multi-Layer Systems

Modern offshore pipeline insulation systems often incorporate multiple layers, including anti-corrosion coatings, thermal insulation layers, and protective outer shells such as high-density polyethylene or concrete weight coating.

Engineered polyol systems are formulated for strong adhesion to steel substrates and compatibility with protective coatings. Proper bonding between layers prevents delamination and ensures mechanical integration of the entire system.

This compatibility enhances overall system reliability, as each layer works in synergy rather than as isolated components.

Customization for Project-Specific Requirements

Every offshore project presents unique challenges based on water depth, fluid composition, temperature range, and installation method. Engineered polyol systems allow manufacturers to tailor properties according to specific project parameters.

Adjustments can be made to:

- Foam density for depth-related pressure resistance

- Reaction profiles for field-applied or factory-applied systems

- Thermal conductivity targets for specific flow assurance strategies

- Flame retardancy requirements for safety compliance

This level of customization ensures that insulation solutions are not generic but precisely aligned with operational needs.

Enhancing Operational Efficiency and Reducing Lifecycle Costs

Long-term reliability translates directly into reduced maintenance and operational costs. Insulation failures in offshore environments are expensive to repair, often requiring specialized vessels and equipment.

By maintaining thermal efficiency and structural integrity over decades, engineered polyol systems minimize the need for intervention. Stable insulation performance supports uninterrupted production, reducing downtime and associated revenue losses.

Additionally, improved flow assurance reduces reliance on active heating systems and chemical injection, lowering energy consumption and environmental impact.

Supporting Sustainability and Environmental Compliance

Sustainability has become an increasingly important consideration in offshore operations. Engineered polyol systems contribute to environmental goals by improving energy efficiency and reducing emissions associated with production interruptions.

Modern formulations may also incorporate environmentally responsible blowing agents with lower global warming potential. Advances in polymer chemistry continue to focus on reducing environmental footprint while maintaining high-performance standards.

Reliable insulation systems help prevent leaks and corrosion-related failures, protecting marine ecosystems and supporting regulatory compliance.

Technological Advancements in Polyol Engineering

Ongoing research and development in polymer science continue to enhance the capabilities of engineered polyol systems. Innovations include improved cell-stabilization technologies, enhanced fire performance, and advanced additives that extend service life.

Digital modeling and simulation tools allow engineers to predict foam behavior under subsea conditions, optimizing formulations before field deployment. This integration of materials science and predictive engineering strengthens confidence in long-term performance.

As offshore exploration moves into deeper and more challenging environments, the evolution of engineered polyol systems will remain essential to meeting future demands.

Conclusion

Offshore pipeline insulation is a critical factor in ensuring safe, efficient, and uninterrupted hydrocarbon transport. The harsh realities of subsea environments demand materials that deliver consistent thermal performance, mechanical strength, water resistance, and dimensional stability over extended service lives.

Engineered polyol systems rise to this challenge by combining advanced chemical design with application-specific customization. Through optimized polymer structures, controlled foam morphology, and tailored formulations, these systems provide durable, reliable insulation solutions that withstand extreme offshore conditions.

By maintaining flow assurance, reducing maintenance requirements, and supporting environmental objectives, engineered polyol systems play a vital role in modern offshore energy infrastructure. Their contribution extends beyond insulation—they underpin the long-term reliability and economic viability of subsea pipeline operations worldwide.