Double V belts may look simple at first, but they play a quiet and powerful role in many machines we use every day. From factory equipment to farming tools, these belts help move energy from one part to another without much noise or trouble. But what makes them different from regular belts? And why are they chosen for some machines and not others?

Let’s break it down in a clear and friendly way.

Note:

If you want to learn more about how Double v Belts(Correas trapezoidales dobles) can fit into different industrial systems, PIX Spain shares useful technical resources and product knowledge on this topic. Contact them to explore practical insights and real-world applications.

What Are Double V Belts?

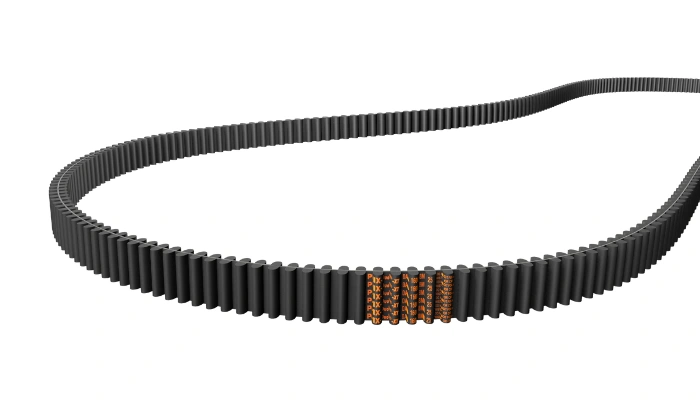

Double V belts are belts that have a “V” shape on both sides. This means they can grip pulleys from the top and the bottom at the same time. Unlike normal belts that only work on one side, these belts are designed to bend and move in more complex systems.

This special shape allows them to run on multiple pulleys and even twist slightly without slipping too much. That is why they are often used in machines where space is tight or where the belt needs to change direction.

At first glance, they may look like just another belt. But once you understand how they are built, their real value becomes clear.

How the Design Makes a Difference

The most interesting part of these belts is their shape. The V shape on both sides is not just for looks. It helps the belt stay in place and hold its grip even when the machine is working hard.

Here is what makes the design special:

- Two-sided grip allows better contact with pulleys

- Flexible body helps the belt bend easily

- Strong outer layer protects from wear

- Firm inner structure keeps the shape stable

This design helps reduce slipping and improves balance. As a result, the machine runs more smoothly and quietly.

Key Parts of the Belt

Every belt is made of a few basic parts that work together.

| Part of the Belt | Purpose | Why It Matters |

|---|---|---|

| Outer layer | Protects the belt | Increases life of the belt |

| Inner cords | Adds strength | Stops stretching |

| V-shaped sides | Improves grip | Reduces slipping |

| Core body | Holds structure | Keeps shape during use |

Each part may seem small, but together they make the belt strong and reliable.

How Double V Belts Work

The main job of these belts is to move power from one part of a machine to another. When one pulley turns, the belt moves and makes the other pulley turn as well.

Because the belt has two V sides, it can work in systems where:

- The belt needs to change direction

- The belt touches more than two pulleys

- The space is limited

- The machine needs smooth movement

This makes them useful in complex setups where regular belts may fail.

Why They Grip So Well

The V shape creates friction between the belt and the pulley. More friction means less slipping. This is important because slipping wastes energy and causes damage over time.

With better grip, the machine does not need to work extra hard. This saves energy and keeps parts from wearing out too fast.

Where Are These Belts Used?

You may not notice them, but these belts are all around us. They are used in many fields because of their flexibility and strength.

Some common applications include:

- Factory machines

- Printing machines

- Textile equipment

- Farming tools

- Packaging systems

- Woodworking machines

In these systems, the belt often needs to move through different angles and paths. That is where this design becomes useful.

Typical Use Cases

| Industry | Example Use | Why This Belt Works |

|---|---|---|

| Manufacturing | Conveyor systems | Handles multiple pulleys |

| Agriculture | Harvesting machines | Works in dusty conditions |

| Printing | Paper feed systems | Smooth and quiet movement |

| Textiles | Spinning machines | Reduces vibration |

| Packaging | Sealing machines | Saves space |

Each use may look different, but the need is the same: reliable movement without trouble.

Benefits That Often Go Unnoticed

Most people only notice a belt when it breaks. But a good belt works silently in the background.

Some key benefits include:

- Smooth operation with less vibration

- Longer life compared to basic belts

- Better control in complex systems

- Lower maintenance needs

- Quiet performance in busy environments

These small advantages add up over time. Machines run better, repairs are fewer, and downtime is reduced.

Common Problems and How to Avoid Them

Even the best belts can face problems if not used correctly.

Some common issues include:

- Belt slipping

- Cracks on the surface

- Noise during operation

- Loss of tension

These problems often happen because of poor installation or lack of care.

Simple Tips for Better Performance

- Check belt tension regularly

- Keep pulleys clean

- Avoid overloading machines

- Replace worn belts on time

A little care can make a big difference. Most failures are not sudden; they give warning signs if you pay attention.

Why These Belts Are Chosen Over Others

People often ask why not just use a flat belt or a normal V belt. The answer lies in flexibility and space.

These belts are chosen when:

- Space is limited

- Direction changes are needed

- Smooth movement is important

- The system is complex

They may not be needed in simple setups, but in advanced systems, they solve problems that other belts cannot.

The Hidden Future of Belt Systems

As machines become smarter and more compact, belt systems also need to improve. Designers now look for parts that are small, flexible, and reliable.

This is where curiosity comes in. What if future machines rely even more on these belts? What if they become the silent heroes of modern automation?

The truth is, we often ignore simple parts until they stop working. But once you understand their role, you start to see them everywhere.

Final Thoughts

Double V belts may seem like just another machine part, but their design shows how small changes can make a big impact. With better grip, flexibility, and balance, they help machines work quietly and smoothly in the background.

They are not flashy. They are not loud. But without them, many systems would struggle to run the way they do today.

FAQs

1. What makes a double-sided belt different from a regular belt?

It has a V shape on both sides, allowing it to grip from both directions.

2. Can these belts be used in small machines?

Yes, they are often used in compact systems where space is limited.

3. Do they need special maintenance?

No, just basic care like regular checks and proper tension.

4. Are these belts noisy?

They usually run quietly if installed correctly.

5. How long do these belts last?

With proper use, they last longer than many basic belt types.

Social Links

Facebook: https://www.facebook.com/pixgermanygmbh/

Instagram: https://www.instagram.com/pixgermanygmbh/

YouTube: https://www.youtube.com/user/pixtrans

LinkedIn: https://www.linkedin.com/company/pixgermanygmbh/

Twitter: https://x.com/pixgermanygmbh

Google Maps: https://maps.app.goo.gl/Ls83bzangT1ipdQv5