In today’s rapidly expanding transmission and distribution networks, utilities and EPC contractors demand overhead conductors that combine mechanical strength, long-span capability, and proven electrical performance. The ACSR Cable (Aluminum Conductor Steel Reinforced) continues to be one of the most widely specified conductors for high-reliability overhead line projects across the world.

As a global manufacturer of overhead conductors and power cables, HNBF Power supplies ACSR cable solutions designed specifically for modern grid infrastructure, substations, and long-distance transmission lines. This guide explains how ACSR cables work, where they are best applied, and what engineers and procurement professionals should evaluate when selecting a reliable ACSR cable supplier.

What Is an ACSR Cable?

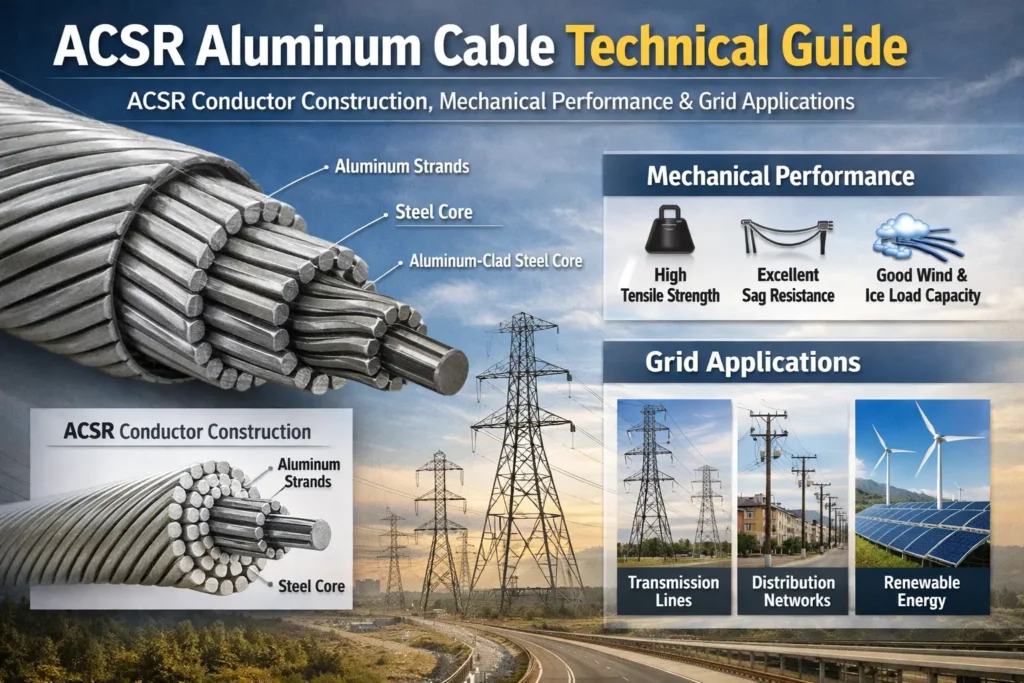

An ACSR cable is a composite overhead conductor made of:

- Outer layers of aluminum strands for electrical conductivity

- A central steel core that provides mechanical strength

This construction allows the conductor to deliver high current capacity while maintaining excellent tensile strength. The steel reinforcement supports heavier spans, reduces sag, and improves resistance to wind and ice loading.

For utilities designing transmission corridors across rivers, valleys, highways, and railways, ACSR remains a benchmark solution for overhead power lines.

Why ACSR Cable Is Widely Used in Power Transmission Projects

High Mechanical Strength for Long Spans

The steel core significantly improves the overall tensile strength of the conductor. Compared with all-aluminum conductors, ACSR cable can safely support:

- Longer span lengths

- Higher conductor tensions

- Challenging terrain crossings

This makes ACSR particularly suitable for transmission lines installed in mountainous and coastal regions.

Balanced Electrical Performance

Although steel is used in the core, the aluminum layers still carry most of the electrical current. This ensures stable conductivity for medium and high-voltage overhead transmission systems.

Key Technical Structure of ACSR Cable

Aluminum Conductor Layers

The outer aluminum strands provide:

- Good electrical conductivity

- Lightweight structure

- Excellent corrosion resistance when properly treated

Different stranding configurations allow engineers to select optimal conductor diameter and current capacity.

Steel Reinforced Core

The steel core delivers:

- High tensile strength

- Reduced conductor sag under high temperatures

- Improved vibration and mechanical fatigue resistance

Together, these components form a robust conductor optimized for both mechanical and electrical performance.

Typical Applications of ACSR Cable in Utility Networks

ACSR cable is widely used in:

- High-voltage and extra-high-voltage overhead transmission lines

- Medium-voltage sub-transmission networks

- Utility grid reinforcement and expansion projects

- Cross-river, highway, and long-span installations

For power utilities and EPC contractors, ACSR cable offers a reliable solution when structural performance is as critical as electrical capacity.

Engineering Advantages of ACSR Cable for Modern Grids

Proven Long-Term Reliability

ACSR cable has been installed worldwide for decades, making its performance behavior well understood by transmission engineers. The steel-reinforced structure performs consistently under:

- Thermal cycling

- Wind-induced vibration

- Mechanical loading

Cost-Effective for Large-Scale Projects

Compared with advanced high-temperature conductors, ACSR offers an economical solution for large route kilometers where:

- Budget efficiency

- Availability

- Standardized installation practices

are essential.

Standards and Quality Requirements

To ensure reliable performance, ACSR cable is typically manufactured according to international standards such as those issued by ASTM International and International Electrotechnical Commission.

These standards define:

- Aluminum and steel wire properties

- Stranding structure

- Mechanical and electrical performance parameters

- Testing and inspection requirements

For utility procurement teams, compliance with recognized international standards is a critical qualification criterion.

How HNBF Power Delivers Reliable ACSR Cable Solutions

As a professional global supplier of overhead conductors, HNBF Power manufactures ACSR cable for utilities, grid operators, and EPC contractors involved in transmission and distribution infrastructure.

HNBF Power’s ACSR cable portfolio supports:

- Multiple conductor sizes and stranding designs

- Custom steel core configurations for special span requirements

- Consistent quality control for large volume supply programs

With a focus on long-term grid reliability, HNBF Power works closely with project engineers to ensure that each ACSR cable specification matches the mechanical loading, environmental conditions, and voltage class of the project.

Key Selection Factors for ACSR Cable Procurement

When specifying ACSR cable for overhead transmission lines, engineers and buyers should evaluate the following:

Mechanical Load and Span Length

The required tensile strength depends on tower spacing, terrain profile, and local weather conditions.

Electrical Current Rating

Conductor size must match the expected operating load and future capacity expansion.

Environmental Conditions

Corrosion exposure, wind, and temperature extremes influence both aluminum and steel performance.

Supplier Manufacturing Capability

Consistent production quality, traceability, and testing capacity are essential for large-scale transmission projects.

HNBF Power supports utility buyers with technical documentation and conductor design assistance to simplify engineering approval and project execution.

FAQs – ACSR Cable

1. What does ACSR cable stand for?

ACSR cable means Aluminum Conductor Steel Reinforced, referring to its aluminum outer layers and steel core.

2. Is ACSR cable suitable for long-span transmission lines?

Yes. The steel core provides the mechanical strength required for long spans, river crossings, and high-load installations.

3. How does ACSR compare with AAAC and AAC conductors?

AAC and AAAC are lighter and have no steel core. ACSR is preferred when higher tensile strength and reduced sag are required.

4. Can ACSR cable be customized for specific projects?

Yes. Stranding structure, aluminum size, and steel core configuration can be customized based on project requirements.

5. Is ACSR cable still relevant for modern grid upgrades?

Absolutely. ACSR remains a widely adopted conductor for new builds and grid reinforcement projects worldwide.

Final Thoughts

ACSR cable continues to play a critical role in building dependable and cost-effective overhead transmission networks. Its proven balance of electrical performance and mechanical strength makes it an ideal solution for utilities and EPC contractors managing demanding infrastructure projects.

Contact HNBF Power today to discuss your ACSR cable requirements and receive customized overhead conductor solutions tailored to your transmission and distribution projects.