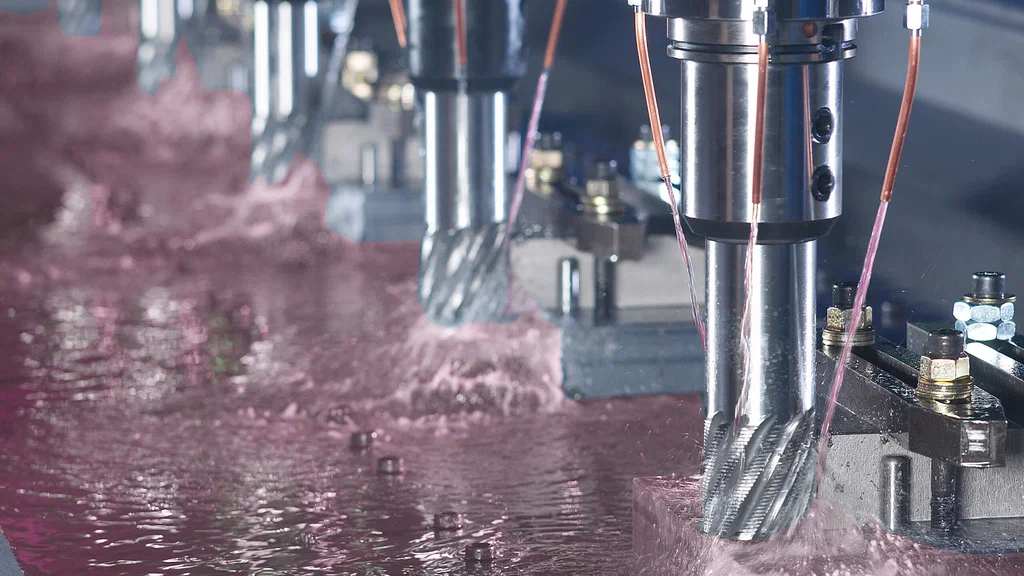

In the UAE’s competitive industrial sector, speed, accuracy, and performance are all essential. In the automotive, aerospace, oil and gas, and metal fabrication industries, one thing that directly affects productivity is the use of high-quality metal cutting fluids. These fluids, often referred to as coolants for metal cutting, play a crucial role in minimizing friction, cooling the tool and workpiece, preventing corrosion, and ensuring clean and efficient cutting.

In the UAE, where the environment is challenging and performance standards are high, selecting the appropriate metal cutting fluid isn’t just about lubrication; it’s also about ensuring your equipment runs smoothly, is safe, and lasts a long time. To get the maximum performance out of your metal cutting fluids in the UAE, here are five essential guidelines to help you choose the right ones.

Understand the Application and Machining Requirements

To choose the correct metal cutting fluid, you need to understand your machining process thoroughly. Different machining tasks, like turning, drilling, grinding, and milling, require different types of cooling and lubrication. For instance, operations that happen at high speeds create more heat and need fluids that carry heat well. On the other hand, operations that involve heavy-duty cutting may need fluids that are very slippery and have additives that can handle intense pressure.

The UAE’s high temperatures also bring their own set of problems, such as increased evaporation and fluid breakdown. A cutting fluid that performs well in moderate conditions may not be as adequate in hot environments like Dubai or Abu Dhabi. This means that thermal stability is a necessary trait to look for when choosing coolants for metal cutting in the UAE.

Consider the Type of Metal Being Machined

Cutting doesn’t affect all metals the same way. The way each metal reacts to machining circumstances is different, and this directly affects the type of metal cutting fluid you should use. For example, aluminum and other softer metals may need fluids that guard against corrosion and offer moderate lubrication without staining the metal. On the other hand, harder metals like titanium or stainless steel get hot and need high-performance synthetic fluids or plain oils that are made to work well under high pressure.

The kind of material also affects the chemistry of the fluid. Some coolants have extra chemicals that can react badly with some metals, causing them to change color or corrode. Choosing a fluid that is right for your material will help your tools last longer, achieve a better surface finish, and extend the lifespan of your machines.

Take Into Account the Local Climate and Operating Conditions

Temperatures in the UAE can easily exceed 45°C, and industrial workshops often face significant heat stress. When choosing a metal cutting fluid, you need to think about the local environment. A liquid that evaporates quickly or becomes unstable when it gets too hot can make things work less well, use more energy, and even break down machinery.

Also, dust, humidity, and water that is high in minerals can all affect how stable and long-lasting your coolant is. It is essential to choose a product that has good heat stability, doesn’t foam up easily, and doesn’t allow bacterial growth. If you use hard water in your coolant mix, choosing fluids that work well with UAE water conditions will help keep things running smoothly and cut down on maintenance problems.

Evaluate Health, Safety, and Environmental Impact

In modern machining, safety and sustainability are becoming increasingly crucial. Given the UAE’s strong emphasis on worker and environmental protection, it’s vital to select metal cutting fluids that are safe for both.

When looking at a cutting fluid, think about what chemicals it is made of. Fluids that don’t have boron, chlorine, or formaldehyde are safer for both workers and the environment. Also, fluids that don’t mist or smell much make workers more comfortable, especially in the UAE’s prevalent enclosed or air-conditioned workshops.

Another important thing is following the rules for the environment. If you want to buy something, be sure it has ISO 14001 or other international certification. Using fluids that break down naturally or can be easily recycled will lower your operations’ impact on the environment and make it easier to deal with trash. Businesses in the UAE can also help the country reach its sustainability goals by using eco-friendly coolants for metal cutting.

Choose a Reliable Local Supplier for Technical Support

When picking a cutting fluid, quality is essential, but so is continuing support and service. There are several benefits to working with a trustworthy metal cutting fluid provider in the UAE. These providers not only sell you the product, but they also offer custom solutions, fluid testing, and help with maintenance.

A good supplier will assist you in determining your business needs, recommend the most suitable fluid type, and provide on-site training for your personnel. Many of the best suppliers in the UAE also offer coolant management programs that monitor concentration, track the fluid’s life, and establish cleaning schedules for the system. This proactive strategy helps cut expenses, make fluids last longer, and reduce unscheduled downtime.

Also, having a local source means speedier delivery, better stock availability, and technical help that takes into account the problems that are common in the area. This is particularly helpful during emergencies or periods of high production when delays are not an option.

Maintenance Matters: How to Keep Your Coolants Working Longer

If you don’t take care of it, even the best metal-cutting fluid will stop working. In the UAE, where dust and high temperatures accelerate the breakdown of fluids, it is crucial to monitor coolants regularly. Using a refractometer to check concentration, monitoring pH and conductivity, and cleaning tanks regularly can all help coolant last longer and make machining work better.

Many places overlook the cost of neglecting their coolant. Dirty or unbalanced fluids can cause tools to shatter, surfaces to be rough, bacteria to thrive, and machines to corrode. With the help of your supplier’s technical staff, a well-kept fluid system will lower these risks and save you money over time.

A standard error is to add plain water to fluids, which can dilute essential ingredients and disrupt the composition’s balance. To keep your coolant working well, always use a premixed solution or add more using the mix ratio that the manufacturer suggests.

Wrap Up on Choosing the Right Metal Cutting Fluids in the UAE

Choosing the correct metal cutting fluid is more than simply a purchase; it’s an essential step toward making your business run more smoothly, protecting your precious equipment, and getting high-quality machining results. With the intense demands of the UAE’s manufacturing environment, making the right choice becomes even more critical.

You can make informed choices with clear benefits by understanding your specific machining processes. Considering the type of metal you’re working with, dealing with environmental issues, and putting safety and supplier support first, it is necessary to make wise choices. The correct coolants for metal cutting will not only make the job go faster, but they will also save expenses, downtime, and harm to the environment.

In the UAE, one of the best things you can do for your business is to buy the correct metal cutting fluids. In today’s world, where accuracy and efficiency are key to success in business, this is one of the best things you can do.