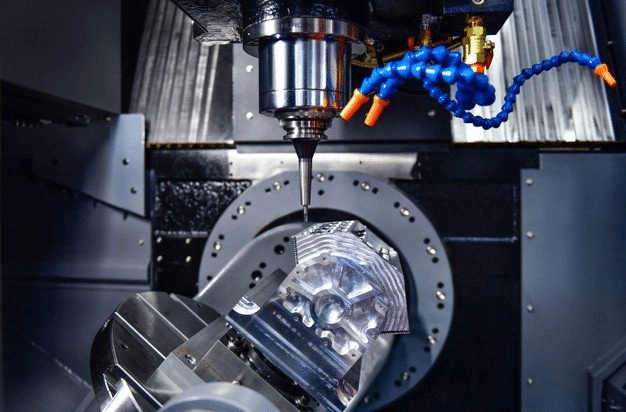

CNC manufacturing depends on control, repeatability, and precision to meet modern industrial demands. Machines continue to evolve, but production quality still relies heavily on how parts are held, positioned, and supported during machining. This is where jigs and fixtures tooling becomes essential, as it creates a stable interface between the CNC machine and the workpiece. When tooling is designed correctly, it reduces variation, improves accuracy, and allows manufacturers to scale production without sacrificing quality.

In competitive CNC environments, efficiency is no longer optional. Manufacturers must reduce setup time, minimize scrap, and maintain tight tolerances across every batch. Advanced tooling strategies help achieve these goals by standardizing machining processes and limiting dependence on manual adjustments. As a result, tooling plays a strategic role in long-term operational success.

Importance of Tooling in CNC Production Systems

Foundation of Machining Accuracy

Tooling acts as the physical reference point for every CNC operation. No matter how advanced the machine control system is, accuracy cannot be achieved if the workpiece shifts during cutting. Proper tooling holds parts securely while maintaining their exact location relative to the cutting tool. This stability ensures dimensions remain consistent throughout the machining cycle.

Accurate tooling also protects cutting tools from uneven loads. By controlling vibration and deflection, fixtures help extend tool life and maintain surface quality. Over time, this leads to lower tooling costs and improved process reliability.

Relationship Between Tooling and Productivity

Productivity improves when machines spend more time cutting and less time adjusting. Well-designed jigs and fixtures reduce setup complexity, allowing operators to load parts quickly and confidently. Repeatable setups mean fewer trial cuts and faster changeovers between jobs.

Consistent tooling also enables higher spindle speeds and feed rates. When parts are held securely, machinists can push machines closer to optimal performance without risking errors.

Key Components of Jigs and Fixtures Tooling

Workholding and Clamping Methods

Workholding determines how a part is secured during machining. Clamps must apply sufficient force to resist cutting loads while avoiding part deformation. The correct balance depends on material type, part geometry, and machining direction. Poor clamping leads to vibration, chatter, and dimensional errors.

Effective tooling designs distribute clamping forces evenly. This improves part stability and ensures repeatable results across multiple cycles.

Locating Systems and Datum Control

Locating defines where a part sits within a fixture. Accurate locating restricts unwanted movement and establishes consistent reference points. Most tooling designs follow structured locating principles that fully constrain the part with minimal contact.

Reliable locating systems speed up loading and reduce operator error. When parts naturally fall into position, setup time decreases and accuracy improves.

How Tooling Enhances CNC Process Efficiency

Reduction of Setup Variability

Setup variability is a major source of inconsistency in CNC machining. Tooling eliminates guesswork by providing fixed references for part placement. Operators no longer rely on visual alignment or manual measurement for each setup.

This predictability shortens preparation time and allows production schedules to remain stable. In high-mix environments, reduced setup variability is especially valuable.

Support for Batch and Mass Production

Batch production demands uniformity. Tooling ensures every part in a batch is machined under identical conditions. This consistency minimizes dimensional variation and simplifies quality control.

For mass production, dedicated fixtures maximize throughput. Once installed, these fixtures allow continuous machining with minimal intervention, supporting high-volume output.

Application of Tooling Across CNC Industries

Automotive and Industrial Equipment

Automotive manufacturing requires precision at scale. Tooling supports rapid machining of engine components, brackets, and housings while maintaining tight tolerances. Fixtures designed for repeat use integrate smoothly with automated production lines.

In industrial equipment manufacturing, tooling supports heavy components and complex geometries. Strong fixtures maintain alignment even under high cutting forces.

Aerospace and Precision Engineering

Aerospace parts often involve thin walls and advanced materials. Tooling must support these components without distortion. Precision fixtures provide controlled contact points, ensuring accuracy while protecting part integrity.

In precision engineering sectors, tooling quality directly affects compliance with strict standards and inspection requirements.

Design Considerations for Effective Tooling

Material Selection and Durability

Tooling materials must withstand repeated use and harsh machining environments. Hardened steel offers durability for long production runs, while aluminum fixtures provide lighter weight and easier handling. Material choice affects fixture life, accuracy, and maintenance needs.

Durable tooling reduces downtime and maintains precision over time. This stability is critical for long-term production planning.

Modular Versus Dedicated Tooling Systems

Manufacturers choose tooling strategies based on production needs. Modular systems offer flexibility and quick reconfiguration, making them suitable for varied product lines. Dedicated tooling delivers maximum efficiency for high-volume, single-part production.

Selecting the right approach depends on batch size, product diversity, and future scalability.

Challenges in Jig and Fixture Implementation

Managing Complex Geometries

Modern CNC parts often feature complex shapes that complicate tooling design. Irregular surfaces require creative locating and clamping solutions. Poorly planned fixtures can introduce stress or misalignment.

Advanced design methods help address these challenges by analyzing forces and contact points before manufacturing begins. Early planning prevents costly redesigns later.

Balancing Cost With Performance

Tooling represents an investment, which can raise concerns about upfront cost. However, low-quality tooling often leads to higher long-term expenses through scrap and rework. Evaluating tooling based on lifecycle value provides a more accurate measure of return.

Well-designed tooling pays for itself through improved efficiency and quality.

Advantages of Professional Jig and Fixture Design

Engineering Knowledge and Experience

Professional designers understand machining dynamics and production constraints. Their experience allows them to create tooling that performs reliably in real-world conditions. This expertise reduces trial and error during implementation.

Experienced design teams also anticipate future production changes, ensuring tooling remains useful as requirements evolve.

Integration With CNC Workflow

Effective tooling integrates seamlessly with CNC programs and inspection processes. When fixtures align with machine paths and measurement strategies, production flows smoothly from setup to final inspection.

This integration reduces friction between departments and improves overall efficiency.

Measuring Tooling Performance in CNC Operations

Productivity and Time Savings

Performance metrics such as cycle time, setup duration, and machine utilization reveal the impact of tooling improvements. Reductions in setup time and increased machine uptime indicate successful implementation.

Tracking these metrics helps justify tooling investments and guide future improvements.

Quality Improvement and Scrap Reduction

Quality metrics provide clear evidence of tooling effectiveness. Lower scrap rates and improved dimensional consistency demonstrate the value of stable workholding and accurate locating. Over time, these improvements strengthen customer trust.

Reliable tooling also simplifies quality audits and documentation.

Future Trends in CNC Tooling Technology

Digital Design and Simulation

Digital design tools allow engineers to simulate fixture behavior before production. This reduces development time and improves first-run success. Simulation-driven design leads to more predictable tooling performance.

As digital tools advance, tooling development becomes faster and more precise.

Automation and Smart Tooling

Smart fixtures equipped with sensors are emerging in advanced CNC environments. These systems monitor clamping force and part presence in real time. Automation-ready tooling supports lights-out manufacturing and scalable production.

Such innovations reduce human error and improve consistency across operations.

Conclusion

Jigs and fixtures tooling plays a decisive role in CNC manufacturing success. It influences accuracy, efficiency, and scalability across all production stages. By investing in well-designed tooling and aligning it with production goals, manufacturers achieve consistent results and long-term competitiveness. As CNC technology advances, tooling will remain a foundational element in delivering reliable and high-quality machining outcomes.